Ford Site ATES District Energy Feasibility Study

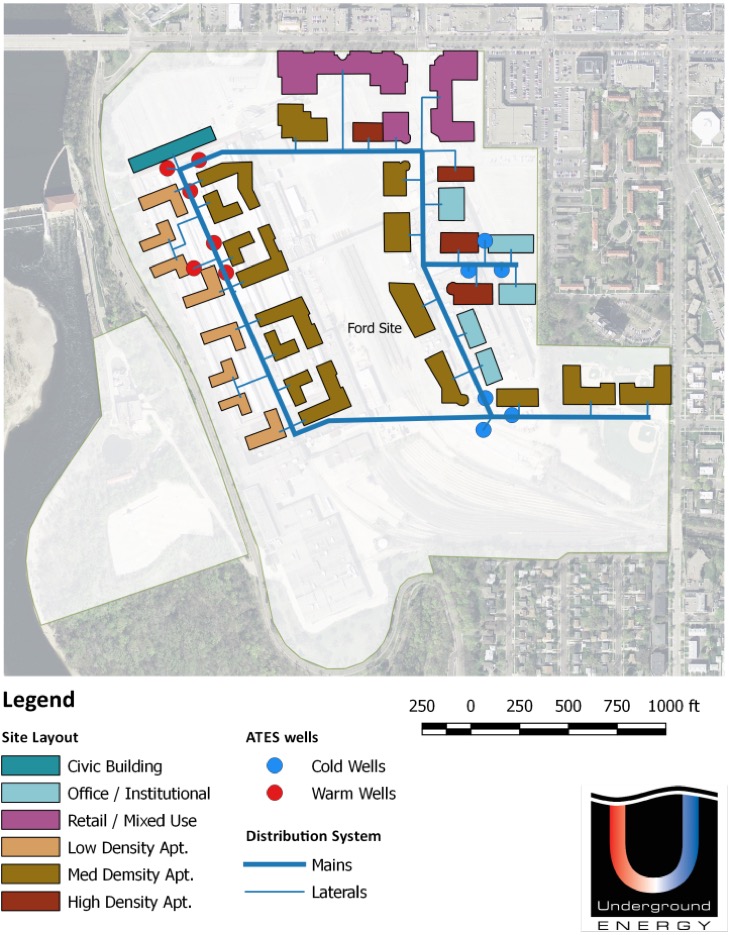

Underground Energy performed an Aquifer Thermal Energy Storage (ATES) feasibility study at the Ford Site for the City of Saint Paul. The 135-acre Ford Site, on the banks of the Mississippi River, is the location of the former Ford Twin Cities Assembly Plant for which a 21st Century Community is envisioned. Ford’s former Twin Cities Assembly Plant will be redeveloped as a livable, mixed use neighborhood that looks to the future with clean technologies and high quality design for energy, buildings and infrastructure.

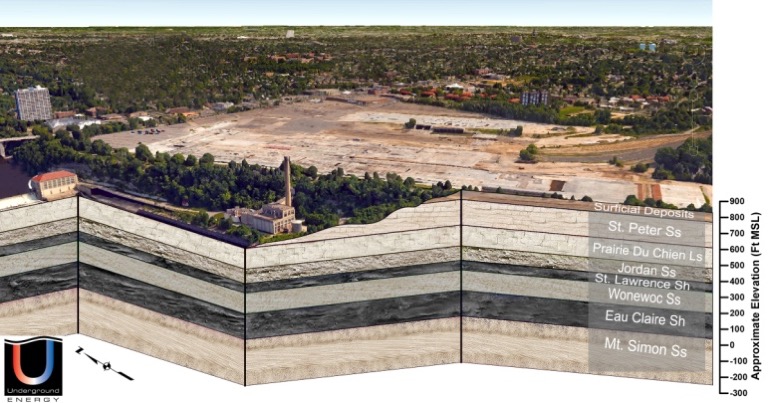

The Minneapolis-St. Paul region is underlain by several high-yield Paleozoic aquifers including the Prairie Du Chien limestone, the Jordon sandstone, and the Mt. Simon sandstone. Aquifer conditions and the climate in the Twin Cities are ideal for ATES, and the large thermal loads at the Ford Site provide an economy of scale that makes ATES a good solution for redevelopment.

Underground Energy’s conceptual design for an ATES system at the Ford Site began with an estimation of heating and cooling loads for about 6.5 million square feet of conditioned space. A diversified heating load of 53.6 million British Thermal Units per hour (MMBtu/h) peak and a diversified cooling load of 3,450 Tons peak was estimated. More than 75% of the annual cooling demand can be met with direct cooling enabled by seasonal thermal energy storage.

The conceptual design is based on boundary conditions that assume the buildings are designed with low-temperature heating systems and high-temperature cooling systems, with each building having its own centralized or individual domestic hot water system(s). Our conceptual design comprises a total of 12 ATES wells (6 warm and 6 cold wells) connected to a 2-pipe groundwater loop that connects heat pumps in individual buildings to the warm and cold ATES wells. A maximum ATES well flow rate of 900 gpm per well (5,500 gpm aggregate) was estimated.

An estimated investment cost of $33 million was calculated for both the ATES system and for the business-as-usual (BAU) scenario of a new, efficient four-pipe district heating & cooling system with centralized gas boilers and electric chillers. Despite their comparable capital costs, the ATES system can provide savings on primary energy consumption of 41% and CO2 emission reductions of 36% compared to the BAU scenario, while eliminating 16 million gallons of water consumption. The estimated ATES operating cost was calculated to be about 17% lower than for the BAU scenario using recent energy prices.